Industrial Ultrasonic Cleaner is an Ideal Cleaning Methods for Parts

Industrial ultrasonic cleaner is mainly used for industrial parts cleaning in factories, which exists in a large number of industrial cleaning areas, ranging from automotive to mechanical engineering, through die casting foundry, plastics and rubber molding, hospital medical industry and many more.

As we all know, Industrial cleaning is undoubtedly a fairly complex process, and ultrasonic cleaning is one of the most efficient industrial cleaning methods. For series of components such as aluminum, steel, rubber or plastic industrial molds or large, turned and worked parts should be washed and maintained, such as those used in aerospace industry, with complicated holes or silhouettes to handle, or even bioethical pliers, surgical instruments or endoscopes.

Some are requiring extremely strict cleaning, with very high standards to be observed in order to preserve its functionality. Such cleaning can also be carried out with traditional maintenance systems, which, however, entail considerable costs not only financial but also staff and time.

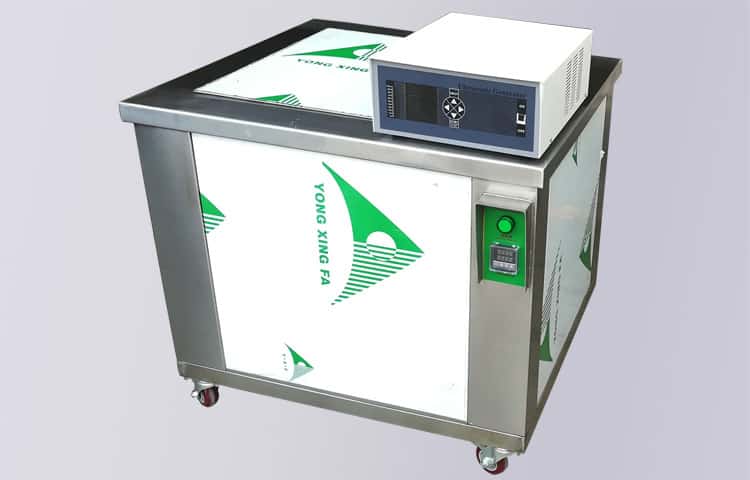

In this regard, a very special type of intervention has been launched, capable of delivering high performance results and safeguarding the treated surfaces without affecting costs. That is the so-called industrial ultrasonic cleaner, a washing system that allows to wash, rinse, protect and dry any surface, even the jagged and extended, or smaller, and so delicate. The ultrasonic cleaner is able to be carried out with low operating costs and no risk, neither for operators nor for the environment.