Here are the custom industrial ultrasonic cleaners for commercial and industrial parts degreasing and cleaning. It is the best ultrasonic parts cleaner for industrial use. This machine comes with high-quality stainless steel ultrasonic cleaning tanks from 60L to 1000L. This kind of large ultrasonic cleaner is sturdy and durable for massive degreasing and cleaning work in factories. So, this is different from that of benchtop series digital ultrasonic cleaners. That’s why we can say it is the best ultrasonic cleaner for industrial use in production lines. But for further understanding of how it works, we’d like to show you more about this. So, you can buy the 60L ultrasonic cleaner, or you can buy the 100L ultrasonic cleaner and more, only if that capacity fits your cleaning needs.

How to Design a Custom Large Industrial Ultrasonic Cleaner?

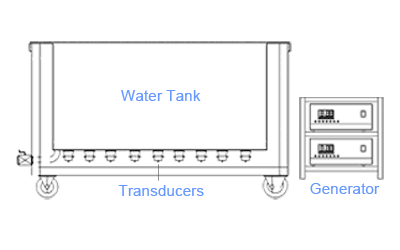

A custom industrial ultrasonic cleaner is engineered around three fundamental components: the cleaning tank, ultrasonic transducers, and heating system. These elements work in unison to deliver efficient, high-performance cleaning for industrial applications. It is one of the best ultrasonic parts cleaners for industrial use.

The core of the system is a heavy-duty ultrasonic cleaning tank, typically constructed from stainless steel for durability and chemical resistance. Mounted to the tank base are the ultrasonic transducers, which generate high-frequency sound waves to create microscopic cavitation bubbles for thorough cleaning. Integrated heating elements are also strategically placed to elevate and maintain solution temperature—enhancing cleaning effectiveness and speeding up processes.

By integrating these core sectors – ultrasonic tanks, transducers, heating, and generator – a custom industrial ultrasonic cleaner can be tailored to meet specific operational needs. Whether for automotive, aerospace, or manufacturing parts cleaning, a purpose-built system ensures optimal compatibility with your materials, contaminants, and production workflow, providing a reliable and scalable solution for industrial parts cleaning challenges.

Custom Large Ultrasonic Tank Dimensions

For industrial-size ultrasonic cleaners, custom ultrasonic tank dimensions are tailored to meet specific cleaning needs, ensuring optimal compatibility with various part sizes and shapes. As a key component of industrial ultrasonic cleaners, ultrasonic cleaning tanks can be fabricated to virtually any measurement – from compact laboratory sizes to large-scale industrial volumes – providing flexibility for automotive, aerospace, and manufacturing applications.

Custom Ultrasonic Frequency

The custom large ultrasonic cleaner features an automatic sweep frequency and variable power function. The most common ultrasonic frequencies are 28KHz and 40KHz for most commercial and industrial use. There are more following ultrasonic frequencies for choice, you may custom 60KHz and 80KHz high frequency ultrasonic cleaner or 28/40KHz dual frequency ultrasonic cleaner, for example.

- Single frequency: 20KHz, 25KHz, 60KHZ, 68KHZ, 80KHZ, 100KHZ, and 120KHZ, and 130KHZ.

- Double frequencies: 28/40KHZ, 25/45KHZ, 32/68KHZ, 40/80KHZ, 40/100KHZ, 40/120KHZ, 40/135KHZ, 80/120KHZ.

| Model | Volume | Ultrasonic Power | Heating Power | Tank Size (MM) |

|---|---|---|---|---|

| KL1018 | 60L | 900W | 2000W | 500x350x350 |

| KL1024 | 88L | 1200W | 4000W | 550x400x400 |

| KL1030 | 100L | 1500W | 4000W | 600x450x400 |

| KL1036 | 150L | 1800W | 6000W | 600x500x500 |

| KL1042 | 175L | 2100W | 6000W | 700x500x500 |

| KL1048 | 200L | 2400W | 6000W | 800x500x500 |

| KL1060 | 240L | 3000W | 9000W | 800x600x500 |

| KL1072 | 300L | 3600W | 9000W | 1000x600x500 |

| KL1120 | 500L | 6000W | 12000W | 1200x700x600 |